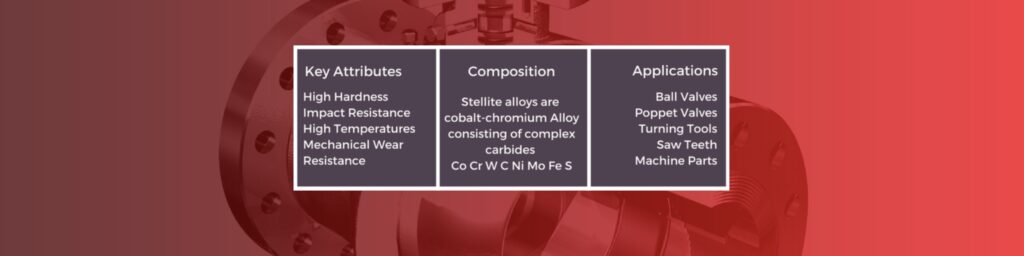

Stellite Alloys are a family of Cobalt- Chromium ‘super alloys’ consisting of complex carbides. They are completely non-magnetic and offer a high level of wear resistance and are particularly effective in providing chemical resistance.

Stellite Alloys are used as a base material, but the disadvantages of this are the high cost of the material and machining. As such it has been adopted as a welding material, but this process is unsuitable for components that might encounter Thermal Distortion and as such HVOF has been developed as a way of getting the properties of Stellite without the cost.

The main advantages with HVOF applied Stellite 6 coatings are that the process does not change the properties of the base material, which may occur during welding. The process can also be carried out on a wider range of base materials and is more precise in nature. At B&B we are able to effectively coat half inch Ball Valves with Stellite 6 coating.

Hardness

Stellite as a metal is that is extremely hard, this makes it difficult to machine which increases lead times and cost. Using the HVOF process we are able to give a components that attributes of Stellite 6 without this cost.

Corrosion Resistance

Stellite 6 provides an excellent corrosion resistance. This is down to the inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix, which allows Stellite 6 coatings to keep their corrosion resistance properties even at high temperatures. Similar to stainless steels, Stellite 6 corrodes primarily through a pitting mechanism and not by general mass loss in seawater and chloride solutions.

Wear Resistance

Stellite 6 is the industry standard for a lot of general purpose wear resistance. This includes many forms of mechanical degradation. Stellite 6 Coatings will keep a high level of hardness up to 500°C. Stellite 6 will also have a good resistance to impact and cavitation erosion.

Welding Alternative

Components are often hardfaced with Stellite through a welding process. The disadvantage of this process is that the Stellite layer will often crack when there is a change in temperature, which will not occur with sprayed Stellite. HVOF can also be performed without fear of thermal distortion.

Applications

Stellite 6 has a wide range of applications but is most popular with our valve customers, where it is often employed as a replacement for Electroless Nickel Plating where the same levels of hardness and corrosion resistance cannot be achieved. It’s also used in a variety of moving parts for machines.