Looking for ceramic coated exhausts?

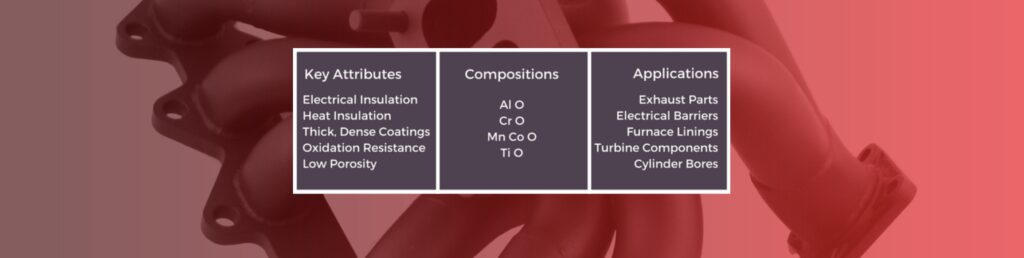

Ceramic as a material has fantastic electrical and heat insulation properties and as such a number of barrier components in different environments have been manufactured in ceramic. The HVOF process allows us to produce thick film ceramic coatings onto a range of different materials.

Electrical Resistance

Ceramics by their nature act as an electrical barrier, but are often brittle in nature, making manufacture potentially difficult. The advantage of the HVOF process is it allows you to selectively coat a component with Ceramic making it an ideal process for the electronics industry for barrier components. Ceramics can also be applied through Physical or Chemical Vapour Deposition, but this process is only suitable for small sized parts, and will only add a thin film of ceramic, where HVOF is an additive process that can be applied to large surfaces. By building up the thickness of the coating, you are able to withstand higher voltages.

Heat Resistance

Ceramic Coatings are also able to provide thermal insulation. Their combination of Heat Resistance, oxidation resistance and low porosity have seen HVOF applied ceramic coatings become widely accepted in the aerospace sector. Other common applications are on car exhausts and furnace linings.

Aluminium Oxide

Aluminium Oxide Coatings provide Electrical and Thermal Resistance properties. They have quite a versatile range of applications and alongside Furnace linings and electrostatic chucks is also used in the medical industry for biomedical implants due to it’s hardness and wear resistance.

Chromium Oxide

Chromium Oxide coatings perform especially well in corrosive chemical environments and are insoluble to acids, alkalis and alcohol when sealed. They can operate at very high temperatures and are a very dense, hard coating.

Titanium Oxide

Used in a variety of industries, Titanium Oxide coatings provide enhanced wear resistance and can operate at high temperatures. They are tough and impact resistant but not as hard as other coatings. Used in Plungers and Pistons.

Manganese Cobalt Oxide

A coating option used on specific applications, Manganese Cobalt Oxide provides good electro-chemical performance at high temperatures and is often used as a means to limit the effects of Chromia evaporation from metal SOFC interconnects.