CNC Machining

- Home

- CNC Machining

High Precision Components

Our Capabilities

Our Services Include

Suitable Components

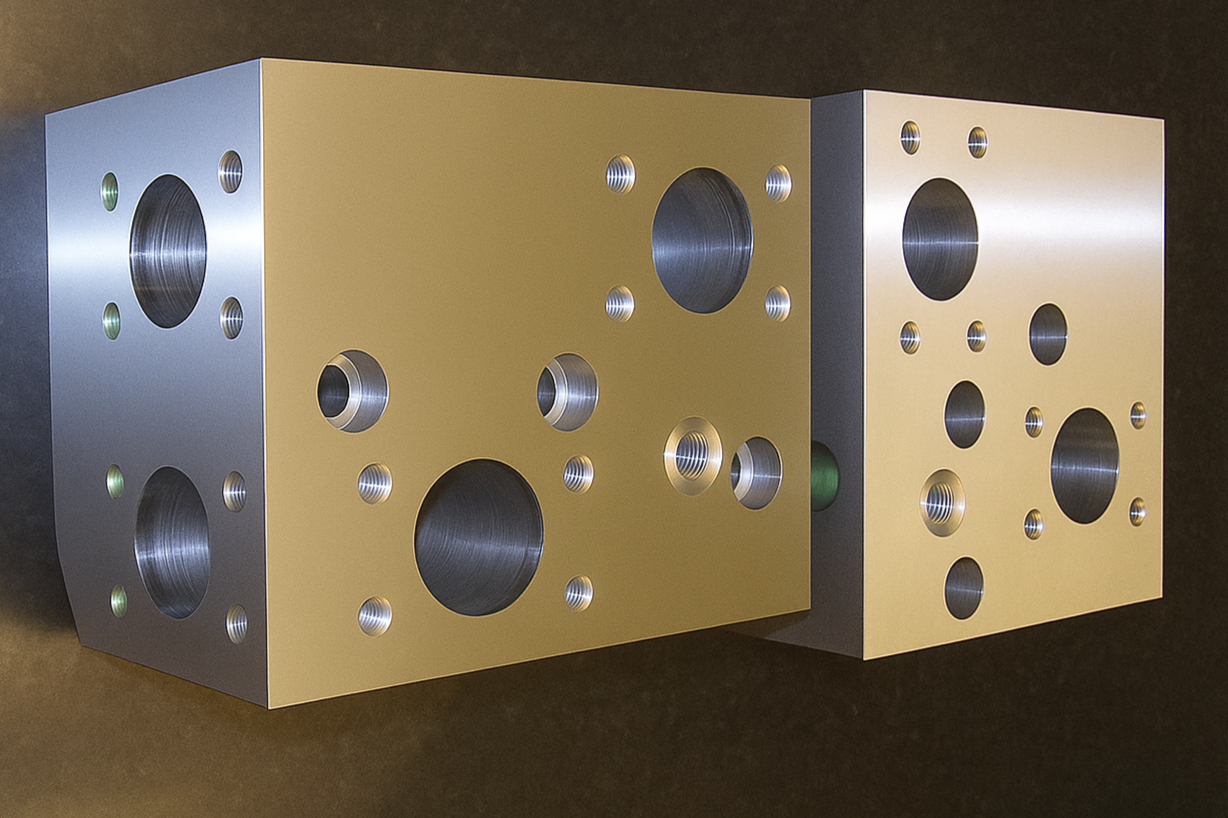

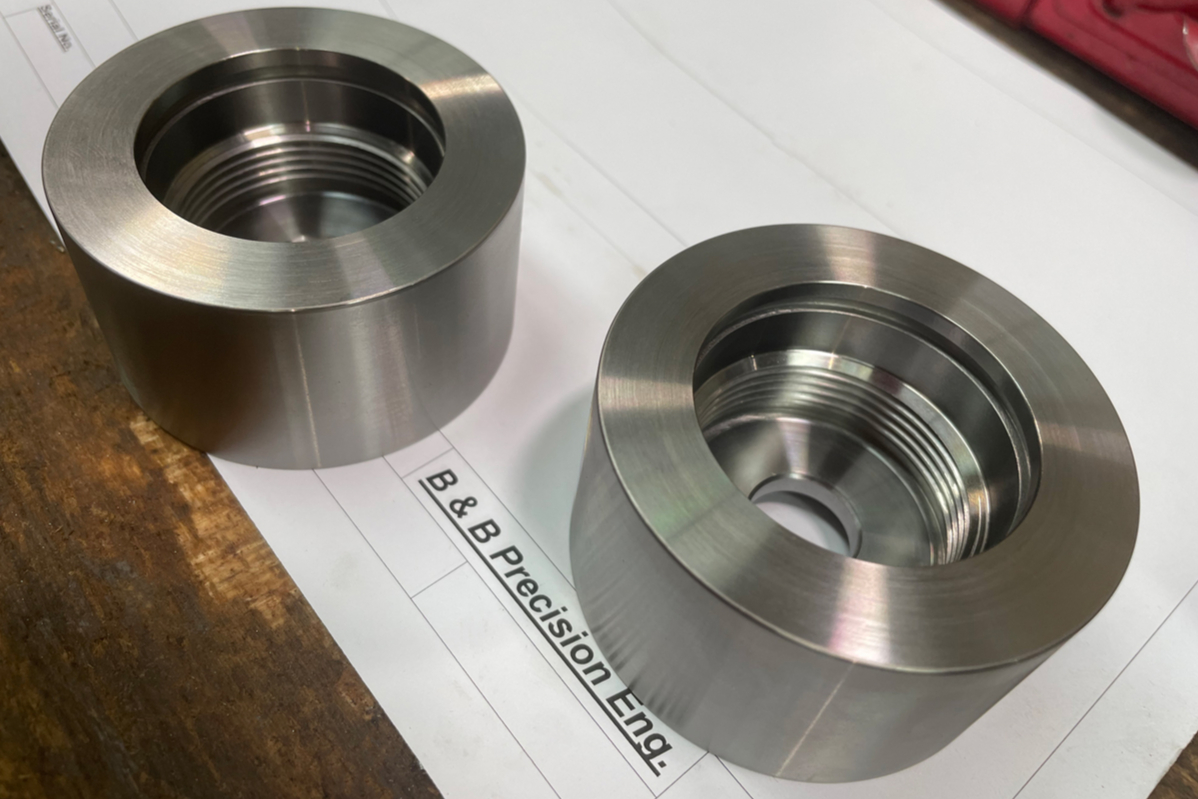

As a sub-contract machinist we have produced a very wide range of components and have a speciality in intricate parts with complicate geometries and tight tolerances. Industries we serve include power generation, oil & gas, automotive as well as a wide variety of OEMS.

Materials

We can work with most engineering materials including but not limited to Carbon and Stainless Steels, Aluminium, Iron, cast materials such as Magnesium, Bronze, engineering plastics such as Nylon and super alloy materials like Hastelloy, Inconel and Kovar.

Supply Complete

B&B are able to provide a full end to end manufacturing service including the sourcing of materials, machining of components as well finishing processes such as plating, painting or heat treatment. This enables our customers to have one point of contact throughout production as well as greater quality oversight.

Delivery

B&B have our own transport that delivers locally within the Yorkshire Region and regularly deliver throughout the UK. We ensure all components are properly packed to minimise any damage during transport. We do have several customers based internationally, please get in touch to discuss your requirements if outside the UK.

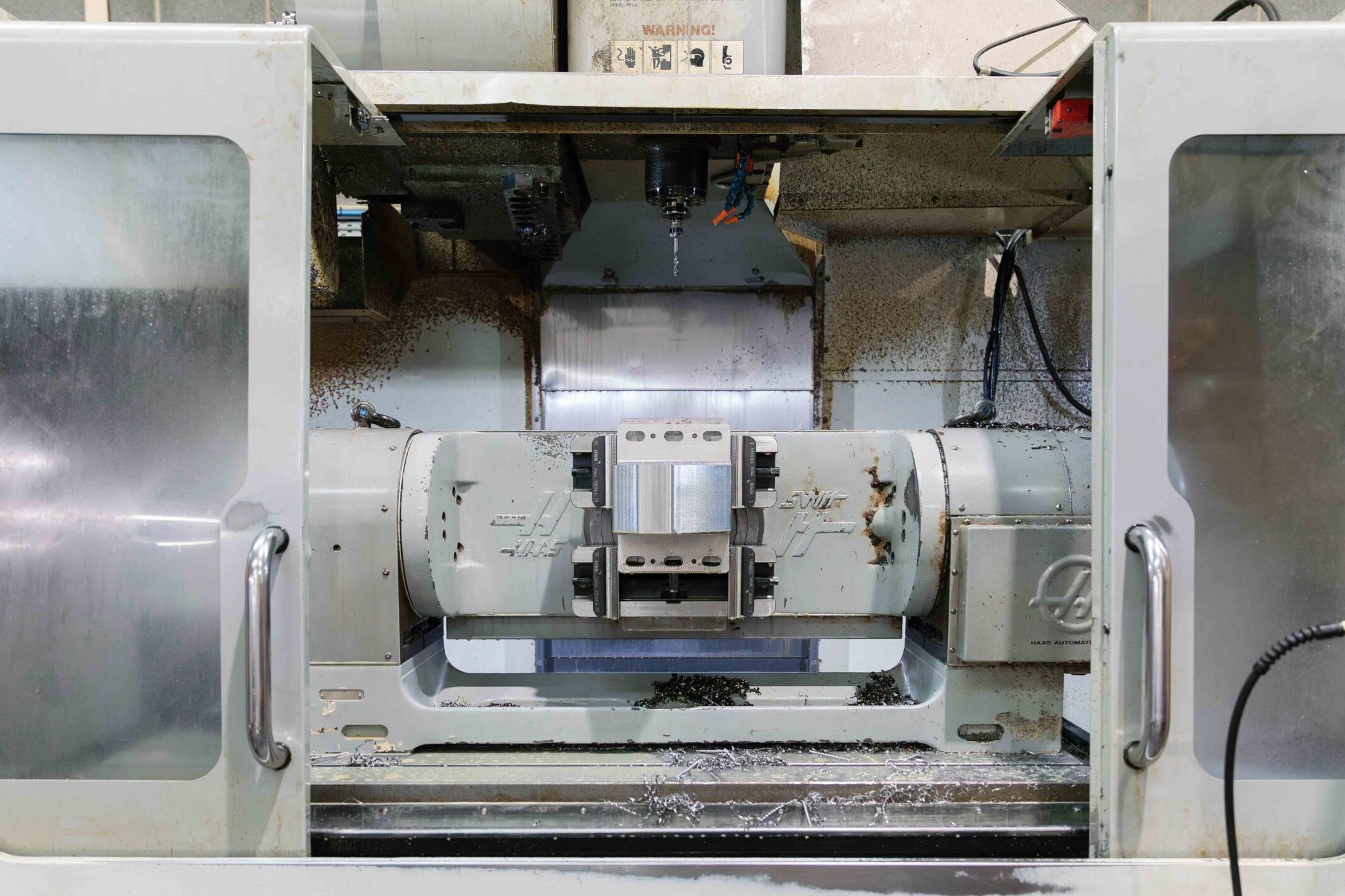

CNC Milling

Haas VF6 Vertical Machine Centre – 1626mm x 813mm x 1062mm

2x Haas VF4 VMC X Vertical Machine Centres- 1270mm x 635mm x 508mm

XYZ 800HD Vertical Machine Centre -800 x 500 x 510 mm

Haas VF2-SS Vertical Machine Centre – 762mm x 406mm x 508mm

Haas TM1-P Vertical Machining Centre – 762mm x 305mm x 406mm

3x XYZ 1500 Manual Milling Machines -Table Size 230mm x 110m

CNC Turning

XYZ XL780 CNC Lathe – Max Diam 780mm x 3000mm

XYZ TC400 CNC Lathe – Max 40mm Dia x 600mm

3x Haas ST30 CNC Lathes – Max Diam 533mm x 76mm Bar

XYZ 250 CNC Lathe – Max Diam 290mm x 76mm Bar

Victor V Turn VT23 CNC Lathe – Max Diam 300mm x 50mm Bar

XYZ CT52 Bar Feed CNC Lathe – Max Diam 208mm x 52mm Bar

3x Manual Turning Machines with a max swing 650mm and Max Distance between centres 2000mm

CNC Grinding

Tschudin TL155U Universal Grinder – Max Diam 505mm x 1.5 metres long

Jones & Shipman Format 15 CNC Grinder – Max Diam 250mm x 70mm between centres

Jones & Shipman Uni Cylinder Grinder – Max Swing 300mm x 850mm between centres

Chruchill Cylindrical Grinder – Max Diam 508mm x 2800mm between centres with DROA

Jones & Shipman 540 Surface Grinder – 450mm x 150mm magnetic table

Snow Hydraulic Horizontal Surface Grinder – Max Diam 310mm x 76mm Bar

Thompson Surface Grinder – 500 x 500 x 250mm magnetic chuck with demagnetiser

EDM WIRE EROSION – 860mm x 580mm x 250mm

Burnett Slotter – with swivel head 200mm stroke fitted with anilam DRO

CADCAM – Solidworks

Company Registration Number

03639121

VAT Number

721236968

DUNS Number

236438573

ISO Certificate

8512-ISO 9001:2015

Contact us

ISO Certificate

8512-ISO 9001:2015

DUNS Number

236438573

Company Registration No.

03639121

VAT Number

721236968